In forehand welding, the angle between the welding torch and the work is More as compared to backhand welding.

140) In fore-hand welding, the angle between the welding torch and the work is ______ As compared to back-hand welding.

more

Related Workshop Technology MCQ with Answers

same

In backhand welding, the angle between the welding rod and the work is same as compared to forehand welding.

carburizing flame and right-ward technique

Linde welding uses Carburising flame and rightward technique.

mild steel

The material which can be best cut with oxygen cutting process is Mild steel.

borax

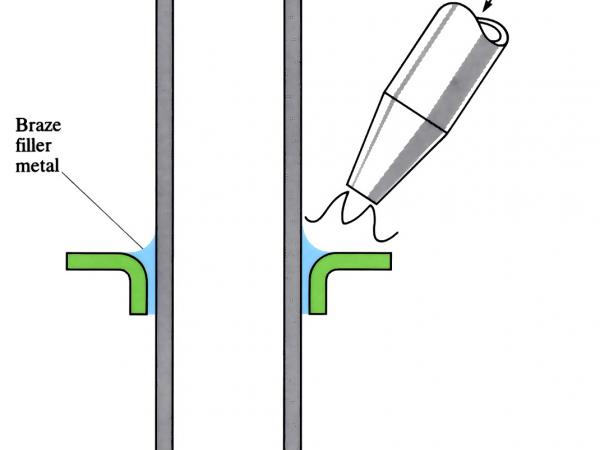

The flux commonly used in brazing is Borax

A flux is required for all brazing and soldering applications.

The purpose of the flux is to remove oxides from the base material and to prevent oxidation during the heating process, thus promoting the free flow of the brazing filler metal.

Brazing is essentially similar to soldering but it gives a much stronger joint than soldering. The principal differences is the use of a harder filler material, commercially known as spelter which fuses at some temperature above red heat, but below the melting temperature of the parts to be joined.

In Brazing most commonly used flux is “Borax” for ferrous and non-ferrous metals. It removes rust and prevents atmospheric effect, when brazing operation is going on