45) Small nose radius

Answer is:

results in excessive stress concentration and greater heat generation

Related Production Engineering MCQ with Answers

Answer is:

The increase in nose radius decreases tool life.

Answer is:

all of these

Explanation:

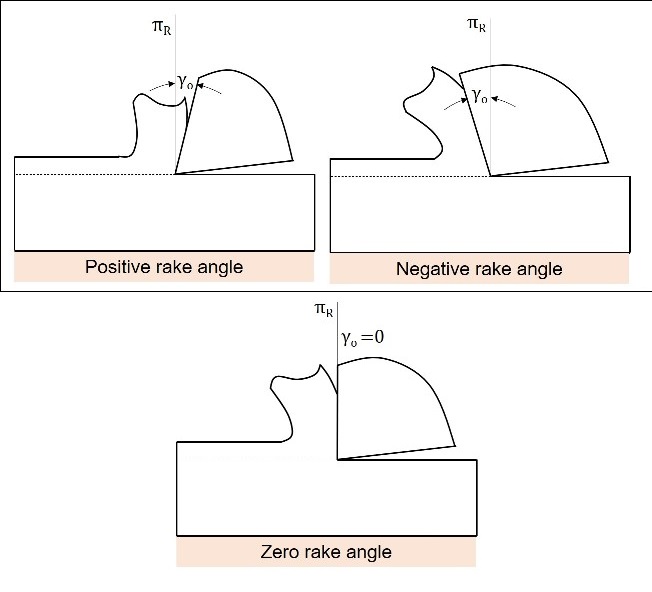

Negative rakes are used for

* carbide tools

* heavy loads

* harder materials

Answer is: